約翰迪爾電噴柴油機的噴油器調整方法與技術資料John Deere強鹿發動機配件RE528708缸墊

約翰迪爾電噴柴油機的噴油器調整方法與技術資料John Deere強鹿發動機配件RE528708缸墊,

Adjust Electronic Unit Injector Preload

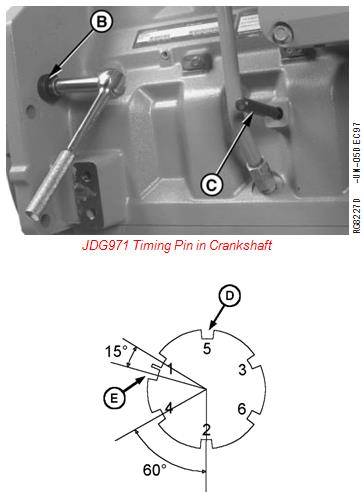

1. Remove plug from cylinder block and install JDG820 Flywheel Turning Tool (B).

IMPORTANT: Timing pin MUST BE installed in slot of camshaft first. Then install second timing pin in crankshaft slot by carefully rocking flywheel back and forth.

2. Rotate engine flywheel in running direction (counterclockwise as viewed from rear) until JDG971 Timing Pin (A) engages single timing slot (D) in camshaft. The proper timing slot can be found by viewing camshaft timing lobe through camshaft timing pin bore while rotating engine. The double timing slot

(E) will be at approximately 11 o’clock (viewed from rear of engine) when pin is installed in slot (D).This ensures that engine is locked at TDC of No. 1 cylinder’s compression stroke. Intake and exhaust rocker arms on No. 1 cylinder should be loose.

3. Remove threaded plug from crankshaft timing hole below oil cooler and filter housing assembly.

IMPORTANT: DO NOT insert timing pin full depth into cylinder block crankshaft timing hole when rotating engine flywheel until double slot on camshaft timing lobe is at approximately 11 o’clock (viewed from rear of engine) to avoid crankshaft counterweight bending timing pin.

4. Slightly move engine flywheel back and forth with turning tool until a second JDG971 Timing Pin (C) can be installed in slot in crankshaft. This ensures that camshaft and crankshaft are in sync (properly timed).

A—JDG971 Timing Pin B—JDG820 Flywheel Turning Tool C—JDG971 Timing Pin

D—Single Timing Slot E—Double Timing Slot

JDG971 Timing Pin in Crankshaft

If timing pin does not enter crankshaft timing slot, crankshaft is not properly timed with camshaft.

Crankshaft MUST BE timed to camshaft. See CHECK AND ADJUST CAMSHAFT-TO-CRANKSHAFT TIMING

in CTM100, Section 02, Group 050.

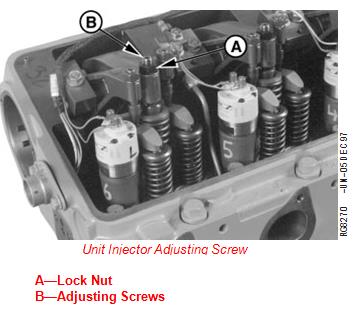

5. Loosen lock nut (A) and loosen cylinders Nos. 3, 5, and 6 injector rocker arm adjusting screws (B) to relieve tension.

6. Slowly tighten adjusting screw until rocker arm roller contacts camshaft lobe at 0.0 clearance.

7. Tighten adjusting screw an additional 1/2 turn (180) to preload injector. Tighten adjusting screw lock nut to specifications while holding adjusting screw stationary.

Specification

Electronic Unit Injector Adjusting Unit Injector Adjusting Screw

Screw Lock Nut—Torque ................................................ 65 N•m (48 lb-ft)

A—Lock Nut

8. Remove both timing lock pins, rotate crankshaft one B—Adjusting Screws

full revolution (360) and pin crankshaft only. Engine will now be locked at No. 6 TDC.

9. Set injector preload on cylinders Nos. 1, 2, and 4.

10. Install plug in timing pin hole in block and tighten to specifications.

Specification

Timing Pin Plug in Cylinder

Block—Torque ................................................................. 33 N•m (24 lb-ft)

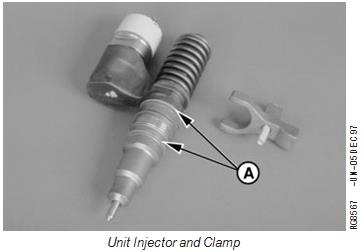

Replace Electronic Unit Injector O-Rings

1. The electronic unit injector’s two external O-rings (A) must be replaced whenever injector is removed.

2. Fuel system diagnosis will determine if unit injector is not functioning properly. Refer to Section 04, Groups 150 and 160, as required.

3. Replaced unit injectors will be returned by your authorized servicing dealer to the manufacturer for testing and rebuilding.

Unit Injector and Clamp

A—O-Rings

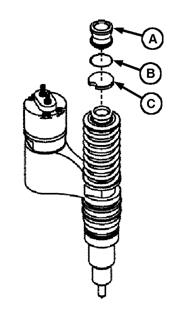

Replace Electronic Unit Injector Thrust Sleeve, Pad and O-Ring

1. Using an O-ring pick, remove O-ring (B).

2. Remove thrust socket (A) and pad (C).

3. Coat parts with clean engine oil and install in reverse order.

A—Thrust Socket B—O-Ring C—Thrust Pad

John Deere Qianglu engine accessories re528708 cylinder gasket, John Deere Qianglu engine accessories re519626 oil filter, John Deere hydraulic pump r986110397 re563594 re587646 re590601, r501124 bolt Bosch 0433171385 fuel injector, dlla144p521 fuel injector supporting DEUTZ Euro 2 fuel injector, Bosch 0433171390 fuel injector, dlla144p527 fuel injector, DEUTZ 04178015 fuel injector, Bosch 0433175229, dlla144p860 fuel injector, DEUTZ 0427175804272558 fuel injector, Bosch 0433171849 injector, dlla144p1369 injector, DEUTZ 02113092 injector, Bosch 0433172009 injector, dlla144p1646 injector, DEUTZ 0432131613, Bosch 0433171871, dlla146p1405 injector, Daewoo injector 0445120040, John Deere Qianglu engine parts, dz108095 driver John Deere Qianglu engine parts, z69500 cutter John Deere Qianglu engine parts, John Deere Qianglu engine parts supply az103851 bearing, John Deere Qianglu engine parts supply re548751 turbocharger, John Deere Qianglu engine parts supply re500199 starter, John Deere Qianglu engine parts supply az103848 input shaft oil seal,

400-100-8969???15088860848

0574-26871589? 15267810868

0574-26886646? 15706865167

0574-26871569 18658287286

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文(簡)

中文(簡) Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韓國

韓國 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska