Perkins柴油發(fā)動機3008搖臂室總成的技術(shù)資料

Perkins柴油發(fā)動機3008搖臂室總成的技術(shù)資料

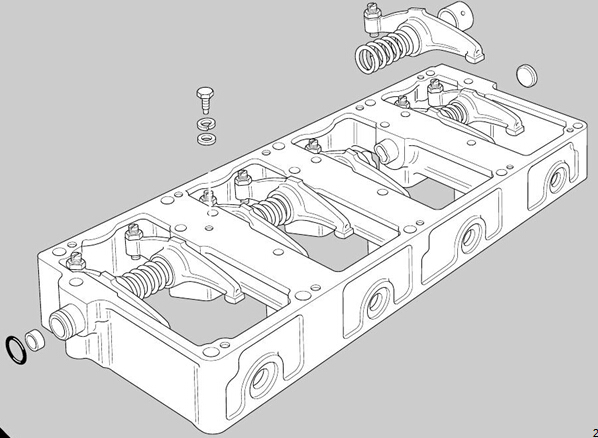

Rocker boxes

To remove and to fit

To remove

12-4

2 Fit a new gasket to the correct position and fit the

rocker box. Fit the setscrews and cap screws of the

rocker box and ensure that the spherical ends of the

roc ker screws are correctly fitted in the sockets of the

push rods .

3 Tighten the setscrews and cap screws evenly until

the correct torque load is obtained.

1 Disconnect and remove the relevant air cleaner,

operation 18-1, and high pressure fuel pipes.

2 Remove the leak-off pipes from the fuel injectors on

the relevant bank and then remove the rocker box

cover.

3 Remove the connectors, for leak-off fuel, from the

fuel injectors.

4 Loosen the adjustment screws of the rockers.

5 Loosen the setscrews and the screws with socket

heads. The pressure of the valve springs will lift the

rock er box away from the cylinder head.

6 Remove the setscrews and cap screws and remove

the rocker box (A).

To fit

1 Ensure that the joint face of the cylinder head is

clean and fit the dowels for the rocker box.

4 Set the tappet clearances, page 39. Fit the

connectors for the leak-off to the fuel injectors,

through the sides of the rocker box, complete with

new sealing washers. Tighten to the correct torque

load.

5 Before the rocker cover is fitted, inspect the 'O' ring

seals for the fuel injectors and renew them if

necessary.

6 Fit a new gasket to the top face of the rocker box,

fit the rocker box cover and setscrews and tighten to

the correct torque load.

The rocker covers of some engines are retained by

ten setscrews and a two nuts.

7 Fit the leak-off pipes.

8 Fit the high pressure fuel pipes, complete with

rubber dampers and shrouds, between the fuel

injection pump and the fuel injectors. Tighten the pipe

connections at the fuel injectors and at the fuel

injection pump to the relevant torque: Engines fitted

with the Bosc h S7100 fuel injection pump, tighten to a

torque of 45 Nm (33 lbf ft). Engines fitted with the

Bosch S3000 fuel injection pump, tighten to a torque

of 25 Nm (15 lbf ft).

9 Ensure that there is no distortion of the high

pressure pipes during this operation.

10 Fit the relevant air cleaner assembly, operation

18-1.

To dismantle and to assemble

To dismantle

12-5

5 If relevant, check that the bore for the cup plug in

the end of the rocker box is clean. Apply 'Loctite 542'

to a new cup plug and press the cup plug into the

rocker box until it is aligned precisely with the wall.

1 If a cup plug is fitted to the bore of the rocker shaft,

it must be removed.

2 Remove the screw that provides the location for the

rocker shaft. Push the rocker shaft in one direction

enough to remove one of the 'O' ring seals from the

end of the shaft. Push the shaft in the other direction

to release the 'O' ring seal from the opposite end.

Continue to withdraw the shaft and remove the rocker

levers and the springs as they become free.

To assemble

1 If relevant, check that the bore for the cup plug in

the end of the rocker box is clean. Apply 'Loctite 542'

to a new cup plug and press it into the bore until it is

aligned with the wall of the rocker box.

2 Apply clean engine lubricating oil to the rocker shaft

and insert the end which has the opening into the bore

of the rocker box. Ensure that the direction of the oil

hole in the rocker shaft is downward (toward the

cylinder head).

3 Push the rocker shaft through the end, enough to fit

the first rocker lever onto the rocker shaft. Continue to

push the rocker shaft through the rocker box and fit

the spring and the second rocker lever before the

rocker shaft enters the first pedestal. Fit the

remainder of the arms and springs in the correct

sequence.

4 Before the rocker shaft is pushed fully into its

correct position, fit the 'O' ring in its groove around the

rocker shaft. Push further the rocker shaft until the

bolt hole in the rocker shaft is aligned with the

threaded hole in the pedestal. Fit the bolt that holds

the rocker shaft, with a plain washer and a spring

washer, and tighten it securely.

6 For rocker boxes which do not have a cup plug in

the bore, insert the shaft into the bore from either end.

Ensure that the oil hole in the rocker shaft is directly

downward (toward the cylinder head). Fit the rocker

levers and the springs in the correct sequence and,

before the rocker shaft is fully into its correct position,

fit a new 'O' ring in the groove around the outer end of

the rocker shaft.

7 Push carefully the rocker shaft through the bore

until the groove at the opposite end is just away from

the wall at the end of the rocker box. Fit the second 'O'

ring and press backward the shaft until the bolt hole in

the rocker shaft is aligned with the threaded hole in

the pedestal. Fit the bolt that holds the rocker shaft,

with a plain washer and a spring washer, and tighten

it securely.

To inspect and to correct

1 Remove all of the grease and dirt from the

12-6

components by the use of a cleaning fluid which can

be diluted with water. Wash and dry each item before

inspection.

2 Inspect the rocker shaft for wear or damage around

the locations of the rocker levers. If wear is seen,

renew the shaft.

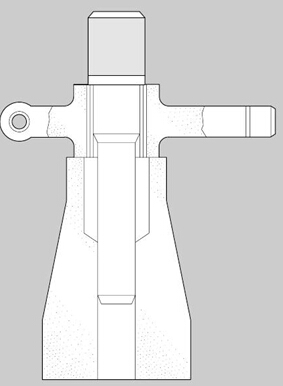

3 Fit each rocker lever onto the shaft and check the

clearance in the bush of the rocker lever. If the

clearance is excessive, make locally a suitable tool as

shown (A) to press out the bush. Make an accurate,

temporary, mark on the rocker lever to indicate the

position of the small cut-out in the end of the bush and

then press out the bush.

4 Check the bore of the rocker lever for deep

scratches or other damage.

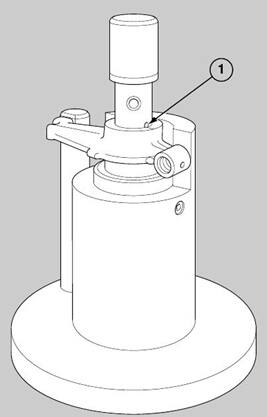

5 If the condition of the rocker lever is acceptable, the

same tool with suitable modifications, similar to the

illustration (B), can be used with a press to fit a new

bush into the roc ker lever. Ensure that the cut-out in

the new bush (B1) aligns exactly with the temporary

mark on the rocker lever. If it does not, press out the

bush and try again. When the operation is finished,

make a final check that the oil holes in the bush are

aligned with the passages in the rocker lever. New

bushes are pre-finished and do not need to be

reamed.

6 Use a fine oilstone to remove small grooves and

scratches and to make a s mooth surface on the pads

of the rocker levers. Ensure that the surface of the

pad is seen to be parallel to the bore by the use of the

roc ker shaft and a straight edge.

400-100-8969???15088860848

0574-26871589? 15267810868

0574-26886646? 15706865167

0574-26871569 18658287286

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文(簡)

中文(簡) Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韓國

韓國 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska